ГЛАВНАЯ>>Пневматический привод>>>Aluminum Pneumatic Actuator

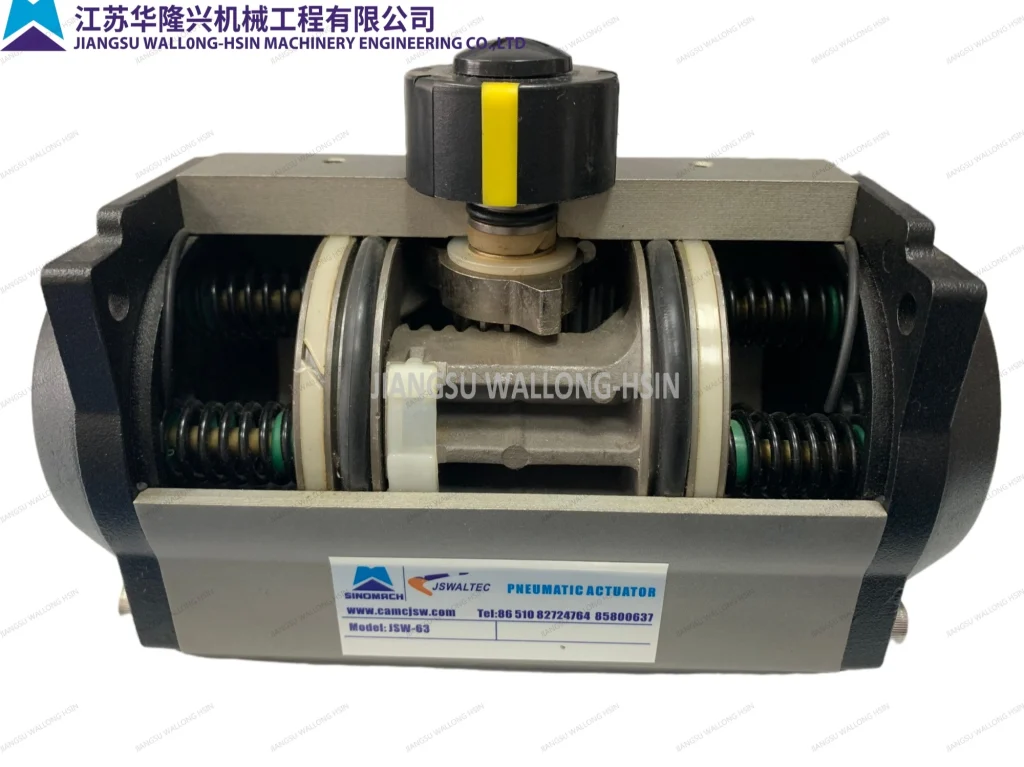

Aluminum Pneumatic Actuator - JSW Series (Double/Single Acting)

Product Overview

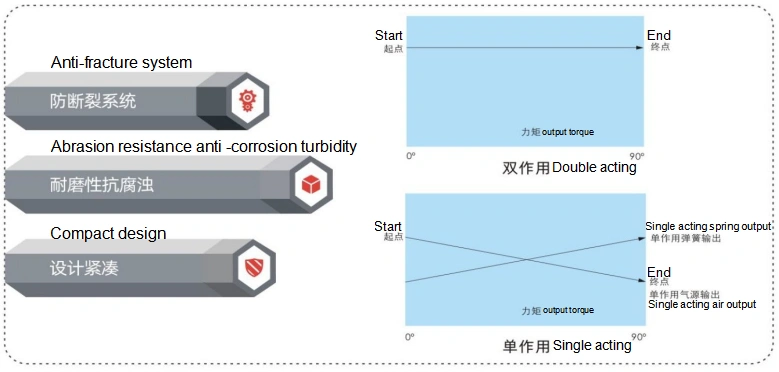

JSW series aluminum pneumatic actuator is an industrial actuating device that uses pneumatic pressure to drive the opening, closing or regulation of valves, dampers, and louvers. It is divided into two types: double acting and single acting. The double acting pneumatic actuator relies on air pressure for both opening and closing actions, while the single acting (spring return) actuator is driven by air pressure when opening and resets via a spring when closing.

Designed for industrial applications, JSW aluminum pneumatic actuators feature a compact structure to save installation space and a modular design that allows direct installation of additional accessories, significantly improving operational efficiency and cost-effectiveness. The cylinder block and piston are made of aluminum alloy with hard anodic oxidation treatment, ensuring excellent corrosion resistance and wear resistance. Compliant with international standards including ISO5211, DIN3337, VDINDE-3854, and NAMUR, our actuators offer strong compatibility and reliable performance in various harsh industrial environments.

What is a Pneumatic Actuator?

What is a Pneumatic Actuator?

Pneumatic actuator is an actuating device that uses pneumatic pressure to drive the opening, closing or regulating of valves. Pneumatic actuators can also be divided into two types: single acting and double acting: the switching action of the actuator is driven by a gas source, which is called Double Acting. The switch action of Spring Return (single acting) is only driven by the air source when it is turned on, and the spring returns when it is turned off.

Pneumatic actuators operate within standard industrial pressure ranges, typically 80 to 100 psi. The common applications: valve and damper control, turbine governors and fluid drives, louvers and inlet vane control.

JSW Actuator Core Advantages

JSW Actuator Core Advantages

- Modular Design: Directly install accessories (e.g., positioners, limit switches) without additional modifications, enhancing work efficiency.

- Compact Structure: Optimized size design saves installation space, suitable for narrow working environments.

- Corrosion & Wear Resistance: Aluminum alloy body with hard anodic oxidation and stainless steel parts ensure long service life in corrosive environments.

- International Standard Compliance: Meets ISO5211, DIN3337, NAMUR standards, compatible with global valve/damper equipment.

- Wide Torque Range: Double acting torque ranges from 4.6 N.m to 12992 N.m, single acting torque adjustable via spring quantity, adapting to various load requirements.

- Cost-Effective: Sophisticated manufacturing processes balance quality and cost, providing high-cost performance for industrial users.

Application

Technical Specifications

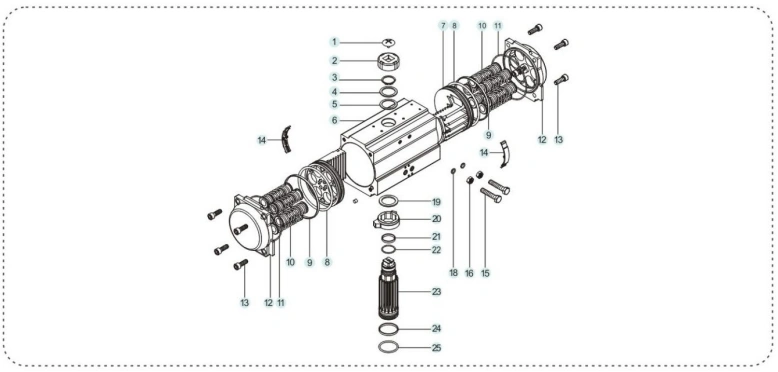

No. | Discription | Qty | Standard Material | Anti-corrode treatment | Optional Material |

1 | Indicator screw | 1 | Plastic |

|

|

2 | Indicator | 1 | Plastic |

|

|

3 | The circlip | 1 | Stainless Steel |

|

|

4 | Washer | 1 | Stainless Steel |

|

|

5 | Outer gasket | 1 | PTFE |

|

|

6 | Cylinder block | 1 | Aluminum alloy | Hard anodic oxidation |

|

7 | Piston | 2 | Aluminum alloy | Hard anodic oxidation | Stainless Steel |

8 | O piston ring | 2 | NBR |

| Fluorine rubber, silicone rubber |

9 | Piston bearing | 2 | Engineering plastics |

|

|

10 | Spring assembly | 0-12 | Spring Steel | Dipping paint |

|

11 | The end cap O ring | 2 | NBR |

| Fluorine rubber, silicone rubber |

12 | The end cover | 2 | Aluminum alloy | Spraying powder |

|

13 | End cover bolt | 8 | Stainless Steel |

|

|

14 | Piston guide | 2 | Engineering plastics |

|

|

15 | Adjusting bolt | 2 | Stainless Steel |

|

|

16 | The adjusting nut | 2 | Stainless Steel |

|

|

17 | Adjusting screw gasket | 2 | Stainless Steel |

|

|

18 | The adjusting O ring | 2 | NBR |

| Fluorine rubber, silicone rubber |

19 | The inner pad | 1 | Engineering plastics |

|

|

20 | Cam | 1 | Alloy steel |

| Stainless Steel |

21 | The upper shaft bearing | 1 | Engineering plastics |

| Fluorine rubber, silicone rubber |

22 | The upper shaft O ring | 1 | NBR |

|

|

23 | Gear shaft | 1 | Alloy steel | Nickel/Chrome | Stainless Steel |

24 | The lower shaft bearing | 1 | Engineering plastics |

|

|

25 | The lower shaft O ring | 1 | NBR |

| Fluorine rubber, silicone rubber |

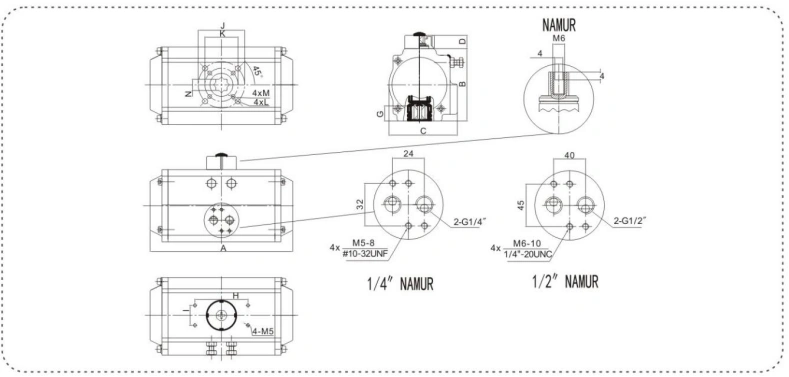

Pneumatic actuator size and connection size diagram

| Модель | A | B | C | D | HxI | G | N | J | K | L | M | Air interface |

| 032 | 110 | 45.5 | 49.5 | 20 | 52X25 | 12 | 9 | Φ36 | M5X7.5 | G1/8’’ | ||

| 040 | 122 | 60 | 65 | 20 | 80X30 | 14 | 11 | Φ50 | Φ36 | M6X10 | M5X7.5 | NAMUR G1/4’’ |

| 052 | 147 | 72 | 72 | 20 | 80X30 | 14 | 11 | Φ50 | Φ36 | M6X10 | M5X7.5 | NAMUR G1/4’’ |

| 063 | 167 | 88 | 83 | 20 | 80X30 | 18 | 14 | Φ70 | Φ50 | M8X13 | M6X10 | NAMUR G1/4’’ |

| 075 | 184 | 100 | 95 | 20 | 80X30 | 20 | 14 | Φ70 | Φ50 | M8X13 | M6X10 | NAMUR G1/4’’ |

| 083 | 210 | 109 | 103 | 20 | 80X30 | 21 | 17 | Φ70 | Φ50 | M8X13 | M6X10 | NAMUR G1/4’’ |

| 092 | 262 | 117 | 109 | 20 | 80X30 | 22 | 17 | Φ70 | Φ50 | M8X13 | M6X10 | NAMUR G1/4’’ |

| 105 | 268 | 133 | 121 | 20 | 80X30 | 26 | 22 | Φ102 | Φ70 | M10X16 | M8X13 | NAMUR G1/4’’ |

| 125 | 301 | 155 | 143 | 20 | 80X30 | 27 | 22 | Φ102 | Φ70 | M10X16 | M8X13 | NAMUR G1/4’’ |

| 140 | 394 | 173 | 152 | 20 | 80X30 | 32 | 27 | Φ125 | Φ102 | M12X20 | M10X16 | NAMUR G1/4’’ |

| 160 | 458 | 198 | 174 | 20 | 80X30 | 34 | 27 | Φ125 | Φ102 | M12X20 | M10X16 | NAMUR G1/4’’ |

| 190 | 528 | 232 | 206 | 30 | 130X30 | 40 | 36 | Φ140 | M16X24 | NAMUR G1/4’’ | ||

| 210 | 532 | 257 | 226 | 30 | 130X30 | 40 | 36 | Φ140 | M16X24 | NAMUR G1/4’’ | ||

| 240 | 608 | 291 | 260 | 30 | 130X30 | 50 | 46 | Φ165 | M20X25 | NAMUR G1/4’’ | ||

| 270 | 716 | 330 | 294 | 30 | 130X30 | 50 | 46 | Φ165 | M20X25 | NAMUR G1/2’’ | ||

| 300 | 820 | 354 | 336 | 30 | 130X30 | 60 | 46 | Φ165 | M20X25 | NAMUR G1/2’’ | ||

| 350 | 926 | 408 | 385 | 30 | 130X30 | 60 | 46 | Φ254 | Φ165 | 8-M16X25 | NAMUR G1/2’’ | |

| 400 | 934 | 464 | 516 | 30 | 130X30 | 60 | 55 | Φ254 | Φ165 | 8-M16X25 | NAMUR G1/2’’ |

JSW actuator output torque

| Модель | input air pressure(bar) | |||||

| 3 | 4 | 5 | 6 | 7 | 8 | |

| output torque(N.m) | ||||||

| DA032 | 4.6 | 6.1 | 7.6 | 9.2 | 10.7 | 12.2 |

| DA040 | 7.2 | 9.6 | 12.0 | 14.4 | 16.8 | 19.2 |

| DA052 | 12.0 | 16.0 | 20.0 | 24.0 | 28.0 | 32.0 |

| DA063 | 21.7 | 28.9 | 36.0 | 43.4 | 50.6 | 57.8 |

| DA075 | 30.0 | 40.0 | 50.0 | 60.0 | 70.0 | 80.0 |

| DA083 | 46.8 | 62.4 | 78.0 | 93.6 | 109.2 | 124.8 |

| DA092 | 67.6 | 90.1 | 112.6 | 135.2 | 157.7 | 180.2 |

| DA105 | 97.7 | 130.3 | 162.9 | 195.5 | 228.0 | 260.6 |

| DA125 | 150.5 | 200.6 | 250.8 | 301.0 | 351.1 | 401.3 |

| DA140 | 260.7 | 347.6 | 433.8 | 521.4 | 608.3 | 695.2 |

| DA160 | 397.2 | 529.6 | 662.0 | 794.4 | 926.8 | 1059.2 |

| DA190 | 640 | 853 | 1067 | 1280 | 1493 | 1707 |

| DA210 | 798 | 1064 | 1330 | 1596 | 1862 | 2128 |

| DA240 | 1154 | 1539 | 1923 | 2308 | 2693 | 3078 |

| DA270 | 1755 | 2340 | 2924 | 3510 | 4095 | 4680 |

| DA300 | 2291 | 3055 | 3819 | 4582 | 5346 | 6110 |

| DA350 | 3426 | 4568 | 5710 | 6852 | 7994 | 9136 |

| DA400 | 4872 | 6496 | 8120 | 9744 | 11368 | 12992 |

| Модель | Spring Qty | Spring output torque(N.m) | Input air pressure(bar) | ||||||||||||

| 3 | 4 | 5 | 6 | 7 | 8 | ||||||||||

| Output torque(N.m) | |||||||||||||||

| 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | ||

| SR160 | 5 | 140 | 193 | 257.5 | 204.5 | 389.5 | 336.5 | 522.5 | 469.5 | 654.5 | 601.5 | 786.5 | 733.5 | 919.5 | 866.5 |

| 6 | 167 | 231 | 229.6 | 166.0 | 361.6 | 298.0 | 494.6 | 431.0 | 626.6 | 563.0 | 758.6 | 695.0 | 891.6 | 828.0 | |

| 7 | 195 | 270 | 201.7 | 127.5 | 333.7 | 259.5 | 466.8 | 392.5 | 598.7 | 524.5 | 730.7 | 656.5 | 863.7 | 789.5 | |

| 8 | 223 | 308 | 173.8 | 89.0 | 305.8 | 221.0 | 438.8 | 354.0 | 570.8 | 486.0 | 702.8 | 618.0 | 835.8 | 751.0 | |

| 9 | 251 | 347 | 145.9 | 50.5 | 277.9 | 182.5 | 410.9 | 315.5 | 542.9 | 447.5 | 674.9 | 579.5 | 807.9 | 712.5 | |

| 10 | 279 | 385 | 118.0 | 12.0 | 250.0 | 144.0 | 383.0 | 277.0 | 515.0 | 409.0 | 647.0 | 541.0 | 780.0 | 674.0 | |

| 11 | 307 | 424 | 222.1 | 105.5 | 355.1 | 238.5 | 487.1 | 370.5 | 619.1 | 502.5 | 752.1 | 635.5 | |||

| 12 | 335 | 462 | 194.5 | 67.0 | 327.2 | 200.0 | 459.2 | 332.0 | 591.2 | 464.0 | 724.2 | 597.0 | |||

| SR190 | 5 | 190 | 320 | 450.5 | 320.0 | 663.5 | 533.0 | 877.5 | 747.0 | 1090.5 | 960.0 | 1303.5 | 1173.0 | 1517.5 | 1387.0 |

| 6 | 227 | 384 | 412.6 | 256.0 | 625.6 | 469.0 | 839.6 | 683.0 | 1052.6 | 896.0 | 1265.6 | 1109.0 | 1479.6 | 1323.0 | |

| 7 | 265 | 448 | 374.7 | 192.0 | 587.7 | 405.0 | 801.7 | 619.0 | 1014.7 | 832.0 | 1227.7 | 1045.0 | 1441.7 | 1259.0 | |

| 8 | 303 | 512 | 336.8 | 128.0 | 549.8 | 341.0 | 763.8 | 555.0 | 976.8 | 768.0 | 1189.8 | 981.0 | 1403.8 | 1195.0 | |

| 9 | 341 | 576 | 298.9 | 64.0 | 511.9 | 277.0 | 725.9 | 491.0 | 938.9 | 704.0 | 1151.9 | 917.0 | 1365.9 | 1131.0 | |

| 10 | 379 | 640 | 261.0 | 0.0 | 474.0 | 213.0 | 688.0 | 427.0 | 901.0 | 640.0 | 1114.0 | 853.0 | 1328.0 | 1067.0 | |

| 11 | 417 | 704 | 436.1 | 149.0 | 650.1 | 363.0 | 863.1 | 576.0 | 1076.1 | 789.0 | 1290.1 | 1003.0 | |||

| 12 | 455 | 768 | 398.2 | 85.0 | 612.2 | 299.0 | 825.2 | 512.0 | 1038.2 | 725.0 | 1252.2 | 939.0 | |||

| SR210 | 5 | 261 | 400 | 537.5 | 398.0 | 803.5 | 664.0 | 1069.5 | 930.0 | 1335.5 | 1196.0 | 1601.5 | 1462.0 | 1867.5 | 1728.0 |

| 6 | 313 | 480 | 485.4 | 318.0 | 751.4 | 584.0 | 1017.4 | 850.0 | 1283.4 | 1116.0 | 1549.4 | 1382.0 | 1815.4 | 1648.0 | |

| 7 | 365 | 560 | 433.3 | 238.0 | 699.3 | 504.0 | 965.3 | 770.0 | 1231.3 | 1036.0 | 1497.3 | 1302.0 | 1763.3 | 1568.0 | |

| 8 | 417 | 640 | 381.2 | 158.0 | 647.0 | 424.0 | 913.2 | 690.0 | 1179.2 | 956.0 | 1445.2 | 1222.0 | 1711.2 | 1488.0 | |

| 9 | 469 | 720 | 329.1 | 78.0 | 595.1 | 344.0 | 861.1 | 610.0 | 1127.1 | 876.0 | 1393.1 | 1142.0 | 1659.1 | 1408.0 | |

| 10 | 521 | 800 | 543.0 | 264.0 | 809.0 | 530.0 | 1075.0 | 796.0 | 1341.0 | 1062.0 | 1607.0 | 1328.0 | |||

| 11 | 573 | 880 | 490.9 | 184.0 | 756.9 | 450.0 | 1022.9 | 716.0 | 1288.9 | 982.0 | 1554.9 | 1248.0 | |||

| 12 | 625 | 960 | 438.8 | 104.0 | 704.8 | 370.0 | 970.8 | 636.0 | 1236.8 | 902.0 | 1502.8 | 1168.0 | |||

| SR240 | 5 | 389 | 583 | 766.0 | 570.0 | 1150.0 | 954.0 | 1535.0 | 1339.0 | 1920.0 | 1724.0 | 2305.0 | 2109.0 | 2689.0 | 2493.0 |

| 6 | 467 | 700 | 688.2 | 453.0 | 1072.2 | 837.0 | 1457.2 | 1222.0 | 1842.2 | 1607.0 | 2227.2 | 1992.0 | 2611.2 | 2376.0 | |

| 7 | 545 | 816 | 610.4 | 336.0 | 994.4 | 720.0 | 1379.4 | 1105.0 | 1764.4 | 1490.0 | 2149.4 | 1875.0 | 2533.4 | 2259.0 | |

| 8 | 622 | 933 | 532.6 | 219.0 | 916.6 | 603.0 | 1301.6 | 988.0 | 1686.6 | 1373.0 | 2071.6 | 1758.0 | 2455.6 | 2142.0 | |

| 9 | 700 | 1049 | 454.8 | 102.0 | 838.8 | 486.0 | 1223.8 | 871.0 | 1608.8 | 1256.0 | 1993.8 | 1641.0 | 2377.8 | 2025.0 | |

| 10 | 778 | 1166 | 761.0 | 369.0 | 1146.0 | 754.0 | 1531.0 | 1139.0 | 1916.0 | 1524.0 | 2300.0 | 1908.0 | |||

| 11 | 856 | 1283 | 683.2 | 252.0 | 1068.2 | 637.0 | 1453.2 | 1022.0 | 1838.2 | 1407.0 | 2222.2 | 1791.0 | |||

| 12 | 934 | 1399 | 605.4 | 135.0 | 990.4 | 520.0 | 1375.4 | 905.0 | 1760.4 | 1290.0 | 2144.4 | 1674.0 | |||

| SR270 | 5 | 505 | 960 | 1250.0 | 845.0 | 1835.0 | 1430.0 | 2419.0 | 2014.0 | 3005.0 | 2600.0 | 3590.0 | 3185.0 | 4175.0 | 3770.0 |

| 6 | 606 | 1152 | 1149.0 | 663.0 | 1734.0 | 1248.0 | 2318.0 | 1832.0 | 2904.0 | 2418.0 | 3489.0 | 3003.0 | 4074.0 | 3588.0 | |

| 7 | 707 | 1344 | 1048.0 | 481.0 | 1633.0 | 1066.0 | 2217.0 | 1650.0 | 2803.0 | 2236.0 | 3388.0 | 2821.0 | 3973.0 | 3406.0 | |

| 8 | 808 | 1536 | 947.0 | 299.0 | 1532.0 | 844.0 | 2116.0 | 1468.0 | 2702.0 | 2054.0 | 3287.0 | 2639.0 | 3872.0 | 3224.0 | |

| 9 | 909 | 1728 | 846.0 | 117.0 | 1431.0 | 702.0 | 2015.0 | 1286.0 | 2601.0 | 1872.0 | 3186.0 | 2457.0 | 3771.0 | 3042.0 | |

| 10 | 1010 | 1920 | 1330.0 | 520.0 | 1914.0 | 1104.0 | 2500.0 | 1690.0 | 3085.0 | 2275.0 | 3670.0 | 2860.0 | |||

| 11 | 1111 | 2112 | 1229.0 | 338.0 | 1813.0 | 922.0 | 2399.0 | 1508.0 | 2984.0 | 2093.0 | 3569.0 | 2678.0 | |||

| 12 | 1212 | 2304 | 1128.0 | 156.0 | 1712.0 | 740.0 | 2298.0 | 1326.0 | 2883.0 | 1911.0 | 3468.0 | 2496.0 | |||

| SR300 | 5 | 725 | 1145 | 1566.0 | 1146.0 | 2330.0 | 1910.0 | 3094.0 | 2674.0 | 3857.0 | 3437.0 | 4621.0 | 4201.0 | 5385.0 | 4965.0 |

| 6 | 870 | 1374 | 1421.0 | 917.0 | 2185.0 | 1681.0 | 2949.0 | 2445.0 | 3712.0 | 3208.0 | 4476.0 | 3972.0 | 5240.0 | 4736.0 | |

| 7 | 1015 | 1603 | 1276.0 | 688.0 | 2040.0 | 1452.0 | 2804.0 | 2216.0 | 3567.0 | 2979.0 | 4331.0 | 3743.0 | 5095.0 | 4507.0 | |

| 8 | 1160 | 1832 | 1131.0 | 459.0 | 1895.0 | 1223.0 | 2659.0 | 1987.0 | 3422.0 | 2750.0 | 4186.0 | 3514.0. | 4950.0 | 4278.0 | |

| 9 | 1305 | 2061 | 986.0 | 230.0 | 1750.0 | 994.0 | 2514.0 | 1758.0 | 3277.0 | 2521.0 | 4041.0 | 3285.0 | 4805.0 | 4079.0 | |

| 10 | 1450 | 2290 | 1605.0 | 765.0 | 2369.0 | 1529.0 | 3132.0 | 2292.0 | 3896.0 | 3056.0 | 4660.0 | 3820.0 | |||

| 11 | 1595 | 2519 | 1460.0 | 536.0 | 2224.0 | 1300.0 | 2987.0 | 2063.0 | 3751.0 | 2827.0 | 4515.0 | 3591.0 | |||

| 12 | 1740 | 2748 | 1315.0 | 307.0 | 2079.0 | 1071.0 | 2842.0 | 1834.0 | 3606.0 | 2598.0 | 4370.0 | 3362.0 | |||

| SR350 | 5 | 1173 | 1703 | 2253.0 | 1723.5 | 3395.0 | 2865.5 | 4537.0 | 4007.5 | 5679.0 | 5149.5 | 6821.0 | 6291.5 | 7963.0 | 7433.5 |

| 6 | 1408 | 2043 | 2018.4 | 1383.0 | 3160.4 | 2525.0 | 4302.4 | 3667.0 | 5444.4 | 4809.0 | 6586.4 | 5951.0 | 7728.4 | 7093.0 | |

| 7 | 1642 | 2384 | 1783.8 | 1042.5 | 2925.8 | 2184.5 | 4067.8 | 3326.5 | 5209.8 | 4468.5 | 6351.8 | 5610.5 | 7493.8 | 6752.5 | |

| 8 | 1877 | 2724 | 1549.2 | 702.0 | 2691.2 | 1844.0 | 3833.2 | 2986.0 | 4975.2 | 4128.0 | 6117.2 | 5270.0 | 7259.2 | 6412.0 | |

| 9 | 2111 | 3065 | 1314.6 | 361.5 | 2456.6 | 1503.5 | 3598.6 | 2645.5 | 4740.6 | 3787.5 | 5882.6 | 4929.5 | 7024.6 | 6071.5 | |

| 10 | 2346 | 3405 | 1080.0 | 21.0 | 2222.0 | 1163.0 | 3364.0 | 2305.0 | 4506.0 | 3447.0 | 5648.0 | 4589.0 | 6790.0 | 5731.0 | |

| 11 | 2581 | 3746 | 1987.4 | 822.5 | 3129.4 | 1964.5 | 4271.4 | 3106.5 | 5413.4 | 4248.5 | 6555.4 | 5390.5 | |||

| 12 | 2815 | 4086 | 1752.8 | 482.0 | 2894.8 | 1624 | 4036.8 | 2766.0 | 5178.8 | 3908.0 | 6320.8 | 5050.0 | |||

| SR400 | 7 | 1837 | 2881 | 3035.2 | 1991.5 | 4659 | 3616 | 6283 | 5240 | 7907 | 6864 | 9531 | 8488 | 11155 | 10112 |

| 8 | 2099 | 3292 | 2773 | 1580 | 4397 | 3204 | 6021 | 4828 | 7645 | 6452 | 9269 | 8076 | 10893 | 9700 | |

| 9 | 2362 | 3704 | 2510 | 1169 | 4134 | 2793 | 5758 | 4417 | 7382 | 6041 | 9006 | 7665 | 10630 | 9289 | |

| 10 | 2624 | 4115 | 2248 | 757 | 3872 | 2381 | 5496 | 4005 | 7120 | 5629 | 8744 | 7253 | 10368 | 8887 | |

| 11 | 2886 | 4527 | 1986 | 346 | 3610 | 1970 | 5234 | 3594 | 6858 | 5218 | 8482 | 6842 | 10106 | 8466 | |

| 12 | 3149 | 4938 | 3347 | 1558 | 4971 | 3182 | 6595 | 4806 | 8219 | 6430 | 9843 | 8054 | |||

| 13 | 3411 | 5761 | 3085 | 1147 | 4709 | 2771 | 6333 | 4395 | 7957 | 6019 | 9581 | 7643 | |||

| 14 | 3674 | 5761 | 2822 | 735 | 4446 | 2359 | 6070 | 3983 | 7694 | 5607 | 9318 | 7231 | |||

| 15 | 3936 | 6173 | 2560 | 324 | 4184 | 1948 | 5808 | 3572 | 7432 | 5196 | 9056 | 6820 | |||

| 16 | 4198 | 6584 | 3922 | 1536 | 5546 | 3160 | 7070 | 4784 | 8794 | 6408 | |||||

FAQ

| Questions | Answers |

|---|---|

| What is the difference between double acting and single acting pneumatic actuators? | Double acting actuators use air pressure for both opening and closing; single acting (spring return) actuators use air pressure for opening and springs for closing, suitable for emergency reset scenarios. |

| Which international standards do JSW actuators comply with? | Our aluminum pneumatic actuators meet ISO5211, DIN3337, VDINDE-3854, and NAMUR standards, ensuring compatibility with global industrial equipment. |

| What materials are used in JSW pneumatic actuators? | Core parts: Aluminum alloy (cylinder block/piston) with hard anodic oxidation; fasteners: Stainless steel; seals: NBR (optional fluorine rubber/silicone rubber); gaskets: PTFE. |

| What is the size range of JSW series actuators? | The size range covers DN45 to DN400 (model 032 to 400), with corresponding torque ranges to adapt to different load requirements. |