INICIO>>Actuador neumático>>Stainless Steel Pneumatic Actuator

JSW Stainless Steel Pneumatic Actuator - Corrosion-Resistant Series

Product Overview

JSW series stainless steel pneumatic actuator is an industrial actuating device driven by pneumatic pressure to control the opening, closing or regulation of valves, dampers, and louvers. It is classified into double acting and single acting types: double acting actuators rely on air pressure for both opening and closing actions, while single acting (spring return) actuators use air pressure for opening and spring force for automatic reset.

Made of high-quality stainless steel for core parts (cylinder block, piston, pinion), this series features excellent corrosion resistance and wear resistance, enabling long-term service in highly corrosive environments. As the first manufacturer in China to produce stainless steel pneumatic actuators with dual independent external travel stop adjustment bolts, JSW integrates exclusive technologies such as fully machined piston teeth and cam inner bores, ensuring precise operation and long durability. Compliant with ISO5211, DIN3337, VDINDE-3854, and NAMUR standards, it is widely used in offshore drilling platforms, shipbuilding, pharmaceuticals, food hygiene, and other demanding industries.

What is a Pneumatic Actuator?

What is a Pneumatic Actuator?

Pneumatic actuator is an actuating device that uses pneumatic pressure to drive the opening, closing or regulating of valves. Pneumatic actuators can also be divided into two types: single acting and double acting: the switching action of the actuator is driven by a gas source, which is called Double Acting. The switch action of Spring Return (single acting) is only driven by the air source when it is turned on, and the spring returns when it is turned off.

Pneumatic actuators operate within standard industrial pressure ranges, typically 80 to 100 psi. The common applications: valve and damper control, turbine governors and fluid drives, louvers and inlet vane control.

JSW Actuator Core Advantages

JSW Actuator Core Advantages

- Superior Corrosion Resistance: Stainless steel cylinder block, piston, and fasteners resist harsh environments (saltwater, chemicals), ideal for offshore and pharmaceutical applications.

- Dual Independent External Adjustment: Exclusive ±5° travel stop adjustment bolts for precise and easy calibration, a pioneering design in China.

- High-Precision Engagement: Fully machined piston teeth and pinion ensure low backlash rack-and-pinion engagement, maximizing transmission efficiency.

- Durable Cam Design: Machined cam inner bore fits the pinion’s curve perfectly, reducing friction and extending service life.

- International Standard Compliance: Meets ISO5211, DIN3337, and NAMUR standards, compatible with global accessories (solenoid valves, positioners).

- Food/Pharmaceutical Grade Adaptability: Stainless steel material and non-toxic seals (Viton/NBR) meet hygiene requirements for food and pharmaceutical industries.

Application

General Industrial Valves/Dampers: For high-corrosion or hygiene-sensitive industrial scenarios requiring reliable operation.

Technical Specifications

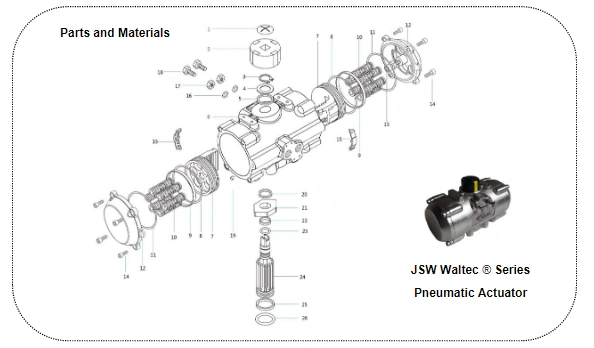

| No. | Description | qty | Standards Material |

| 1 | Indicatr Serw | 1 | Plastic |

| 2 | Indicator | 1 | Plastic |

| 3 | Snap Ring | 1 | Stainlessstel |

| 4 | Washer | 1 | Stairless steel |

| 5 | Outside Washer | 1 | Engineering Plastic |

| 6 | Cylinder block | 1 | Stairless steel |

| 7 | Piston | 2 | Stainless seel |

| 8 | Piston O-ring | 2 | Viton/NBR |

| 9 | Piston Bearing | 2 | Engineering Plastic |

| 10 | Spring | 0-12 | Spring Steel |

| Sprina RetainerlL.R) | 66 NMon 66 | ||

| Retainer Connector | Brass | ||

| 11 | End-Cap O-ring | 2 | VitonINBR |

| 12 | End-Cap | 2 | Stairlesseel |

| 13 | Stop screw | 2 | Stainless steel |

| 14 | End-Cap Stop Screw | 8 | Stainless steel |

| 15 | Guide Piston | 2 | 66 Nylon 66 |

| 16 | Oring(Adjiust screw) | 2 | NBR |

| 17 | Nut(Adiust screw) | 2 | Stainless steel |

| 18 | Adjiust screw | 2 | Stainless stel |

| 19 | Plug | 2 | NBR |

| 20 | Inside Washer | 1 | Engineering Plastic |

| 21 | Cam | 1 | Stairless steel |

| 22 | Bearina Top | 1 | Engineering Plastic |

| 23 | O-ring(Top) | 1 | VitonINBR |

| 24 | Pinion | 1 | Stainless steel |

| 25 | Bearing Bottom | 1 | Engineering Plastic |

| 26 | O-ring Bottom | 1 | Viton/NBR |

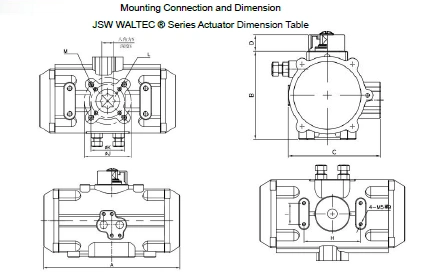

Pneumatic actuator size and connection size diagram

| Modelo | A | B | C | D | G | Hx1 | N | J | K | L | M | Air Connection |

| JSW-45 | 138 | 64 | 77 | 20 | 14 | 80×30 | 11 | Φ50 | Φ36 | 4-M6x10 | 4-M5x7.5 | NPT1/4″ |

| JSW-52 | 146 | 72 | 79 | 20 | 14 | 80×30 | 11 | Φ50 | Φ36 | 4-M6x10 | 4-M5x7.5 | NPT1/4″ |

| JSW-63 | 173 | 88 | 92 | 20 | 18 | 80×30 | 14 | Φ70 | Φ50 | 4-M8x13 | 4-M6x10 | NPT1/4″ |

| JSW-83 | 204 | 108 | 113.5 | 20 | 21 | 80×30 | 17 | Φ70 | Φ50 | 4-M8x13 | 4-M6x10 | NPT1/4″ |

| JSW-105 | 270 | 133 | 137 | 20 | 26 | 80×30 | 22 | Φ102 | Φ70 | 4-M10x16 | 4-M8x13 | NPT1/4″ |

| JSW-125 | 302 | 155 | 157 | 20 | 27 | 130×30 | 22 | Φ102 | Φ70 | 4-M10x16 | 4-M8x13 | NPT1/4″ |

| JSW-140 | 394 | 172 | 173 | 20 | 32 | 130×30 | 27 | Φ125 | Φ102 | 4-M12x20 | 4-M10x16 | NPT1/4″ |

| JSW-160 | 456 | 198 | 193 | 20 | 34 | 13.x30 | 27 | Φ125 | Φ102 | 4-M12x20 | 4-M10x16 | NPT1/4″ |

| JSW-210 | 568 | 257 | 246 | 30 | 40 | 130×30 | 36 | Φ140 | / | 4-M16x24 | / | NPT1/4″ |

| JSW-24D | 608 | 291 | 260 | 30 | 50 | 130×30 | 46 | Φ165 | / | 4-M20x25 | / | NPT1/4″ |

| JSW-300 | 820 | 354 | 336 | 30 | 60 | 130×30 | 46 | Φ165 | Φ165 | 4-M20x25 | M20x25 | NPT1/2″ |

| JSW-400 | 934 | 464 | 516 | 30 | 60 | 130×30 | 55 | Φ254 | Φ165 | 8-M16x25 | M20x25 | NPT1/2″ |

Air supply connection is designed in accordancewith NAMUR Standard to install solenoid valves.

The Namur drive pinion and the Namur top mounting connection permit direct installation of accessories such as limit switch box and positioner.

Bottom mounting connection is designed in accordance with ISO5211 and DIN3337 standards for direct mounting with valve gear boxes or mounting brackets.

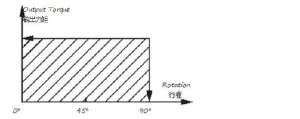

Output Torque Table of JSW WALTEC ® Series Pneumatic Actuators with Double Acting

Air pressure(Bar) | ||||||

Modelo | 3 | 4 | 5 | 6 | 7 | 8 |

Output Torque of Air to Springs (Nm) | ||||||

JSW-45DA | 9.1 | 12.1 | 15.1 | 18.1 | 21.1 | 24.1 |

JSW-52DA | 12 | 16 | 20 | 24 | 28 | 32 |

JSW-63DA | 21.7 | 28.9 | 36.1 | 43.3 | 50.6 | 57.8 |

JSW-83DA | 42.8 | 57 | 71.3 | 85.5 | 99.8 | 114 |

JSW-105DA | 97.7 | 130.3 | 162.9 | 195.5 | 228 | 260.6 |

JSW-125DA | 173.3 | 231 | 288.8 | 346.5 | 404.3 | 462 |

JSW-140DA | 260.7 | 347.6 | 434.5 | 521.4 | 608.3 | 695.2 |

JSW-160DA | 397.2 | 529.6 | 662 | 794.4 | 926.8 | 1059.2 |

JSW-210DA | 798 | 1064 | 1330 | 1596 | 1862 | 2128 |

JSW-240DA | 1154.3 | 1539 | 1923.8 | 2308.5 | 2693.3 | 3078 |

JSW-300DA | 2291.4 | 3055.2 | 3819 | 4582.8 | 5346.6 | 6110.4 |

JSW-400DA | 4872 | 6496 | 8120 | 9744 | 11368 | 12992 |

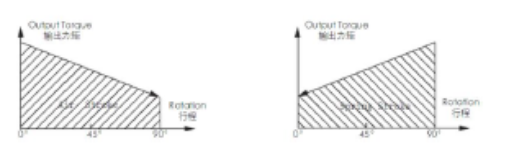

Modelo | Spring | Springs’ output | 3 | 4 | 5 | 6 | 7 | ||||||

Output Torque of Air to Springs (Nm) | |||||||||||||

0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | ||

start | end | start | end | start | end | start | end | start | end | start | end | ||

JSW-45SR | 2 | 4.6 | 7.4 | 4.2 | 1.3 | 7.2 | 4.3 | 10.2 | 7.3 | ||||

3 | 5.8 | 9.2 | 6 | 2.4 | 9 | 5.4 | 12 | 8.4 | 15 | 11.4 | |||

4 | 7 | 11.1 | 7.8 | 3.5 | 10.8 | 6.5 | 13.8 | 9.5 | |||||

JSW-52SR | 5 | 3.6 | 5.4 | 6.5 | 4.6 | 10.8 | 8.6 | ||||||

6 | 4.3 | 6.7 | 6 | 3.3 | 10.2 | 7.3 | |||||||

7 | 5.1 | 7.9 | 9.6 | 6.1 | 13.7 | 10.1 | |||||||

8 | 5.8 | 9.2 | 9 | 4.8 | 13 | 8.8 | |||||||

9 | 6.6 | 10.4 | 8.4 | 3.6 | 12.4 | 7.6 | 16.4 | 11.6 | |||||

10 | 7.3 | 11.7 | 7.8 | 2.3 | 11.8 | 6.3 | 15.7 | 10.3 | 19.6 | 14.3 | |||

11 | 8.1 | 12.9 | 11.1 | 5.1 | 15 | 9.1 | 18.8 | 13.4 | |||||

12 | 8.8 | 14.2 | 10.5 | 3.8 | 14.3 | 7.8 | 18 | 11.8 | |||||

JSW-63SR | 5 | 6.1 | 12 | 16.3 | 10.6 | 23.2 | 17.7 | ||||||

8 | 7.3 | 13.7 | 14.5 | 7.9 | 21.4 | 15 | |||||||

7 | 8.6 | 15.5 | 19.7 | 12.4 | 26.6 | 19.5 | |||||||

8 | 9.8 | 17.2 | 17.9 | 9.8 | 25 | 17 | |||||||

9 | 11.1 | 19 | 16.2 | 7.2 | 23.3 | 14.4 | 30.4 | 21.7 | |||||

10 | 12.3 | 20.7 | 14.4 | 4.5 | 21.6 | 11.9 | 28.8 | 19.2 | 35.9 | 26.5 | |||

11 | 13.6 | 22.5 | 19.9 | 9.3 | 27.1 | 16.7 | 34.4 | 24.1 | |||||

12 | 14.8 | 24.2 | 18.2 | 6.7 | 25.5 | 14.2 | 32.8 | 21 | |||||

JSW-83SR | 5 | 15 | 20.4 | 30.2 | 22.8 | 45.3 | 39.2 | ||||||

8 | 18 | 24.6 | 26.9 | 17.6 | 41.9 | 33.9 | |||||||

7 | 21 | 28.7 | 38.5 | 28.6 | 53.4 | 44.8 | |||||||

8 | 24 | 32.9 | 35.1 | 23.2 | 29.9 | 39.3 | |||||||

9 | 27 | 37.1 | 31.6 | 17.9 | 46.5 | 33.8 | 61.3 | 49.8 | |||||

10 | 30 | 41.2 | 28.2 | 12.6 | 43 | 28.4 | 57.7 | 44.2 | 72.5 | 60.1 | |||

11 | 33 | 45.4 | 39.5 | 22.9 | 54.2 | 38.6 | 68.9 | 54.3 | |||||

12 | 36 | 49.6 | 36 | 17.5 | 50.6 | 33.1 | 65.3 | 48.6 | |||||

JSW-105SR | 5 | 30.3 | 45.4 | 59.9 | 44.5 | 92.1 | 75.5 | ||||||

8 | 36.4 | 54.7 | 54.7 | 36.5 | 86.3 | 67.1 | |||||||

7 | 42.6 | 63.8 | 80.6 | 58.7 | 111.9 | 88.8 | |||||||

8 | 48.7 | 72.9 | 75 | 50.3 | 105.7 | 80 | |||||||

9 | 54.9 | 82.2 | 69.2 | 41.9 | 9.5 | 71.2 | 129.9 | 100.4 | |||||

10 | 60.9 | 91.3 | 63.5 | 33.5 | 93.4 | 62.3 | 123.2 | 91.1 | 153.1 | 119.9 | |||

11 | 67.1 | 100.4 | 87.2 | 53.5 | 116.6 | 81.8 | 146.1 | 110.2 | |||||

12 | 73.3 | 109.7 | 81.1 | 44.6 | 110.1 | 72.5 | 139 | 100.4 | |||||

JSW-125SR | 5 | 48.3 | 72.3 | 103.4 | 77.5 | 154.7 | 123.9 | ||||||

8 | 56 | 86.4 | 92.8 | 59.8 | 143.6 | 106.9 | |||||||

7 | 65.8 | 100.6 | 132.5 | 89.9 | 182.9 | 137.9 | |||||||

8 | 75.5 | 114.8 | 121.4 | 72.9 | 171.3 | 121.6 | |||||||

9 | 85.3 | 128.9 | 110.4 | 55.9 | 159.7 | 105.4 | 209 | 154.8 | |||||

10 | 95 | 143.1 | 99.3 | 38.9 | 158.1 | 89.1 | 196.9 | 139.3 | 245.8 | 189.4 | |||

11 | 104.8 | 157.3 | 136.5 | 72.9 | 184.9 | 123.8 | 233.2 | 174.7 | |||||

12 | 114.5 | 171.4 | 124.9 | 56.6 | 172.8 | 108.3 | 220.6 | 159.9 | |||||

JSW-140SR | 5 | 74.7 | 113.6 | 177 | 135.4 | 258.7 | 219.4 | ||||||

8 | 90.9 | 139.6 | 158.2 | 105.3 | 240.7 | 190 | |||||||

7 | 107.1 | 165.6 | 222.7 | 160.6 | 306 | 245.9 | |||||||

8 | 123.2 | 191.6 | 204.7 | 131.2 | 288.7 | 217.1 | |||||||

9 | 139.4 | 217.6 | 186.7 | 101.8 | 271.5 | 177.3 | 356.2 | 274.8 | |||||

10 | 155.6 | 243.6 | 168.7 | 72.3 | 254.2 | 159.5 | 339.7 | 246.7 | 425.2 | 333.8 | |||

11 | 171.7 | 269.6 | 237 | 130.7 | 323.2 | 218.5 | 409.5 | 306.3 | |||||

12 | 187.9 | 295.6 | 219.7 | 101.9 | 306.7 | 190.3 | 393.7 | 278.8 | |||||

JSW-160SR | 5 | 112.4 | 190.9 | 267.7 | 183 | 397.4 | 316.9 | ||||||

8 | 137.4 | 229.9 | 239.4 | 140.3 | 369.6 | 273.5 | |||||||

7 | 162.5 | 268.9 | 211.1 | 97.6 | 341.8 | 130.1 | 472.3 | 362.5 | |||||

8 | 187.6 | 307.9 | 313.9 | 186.7 | 444.9 | 318.3 | |||||||

9 | 212.7 | 346.9 | 286.1 | 143.3 | 417.4 | 274.2 | 548.7 | 405.1 | |||||

10 | 237.8 | 375.9 | 258.3 | 99.8 | 389.9 | 230 | 521.6 | 360.2 | 653.3 | 490.3 | |||

11 | 262.9 | 424.9 | 362.5 | 185.8 | 494.5 | 315.3 | 26.6 | 444.7 | |||||

12 | 287.9 | 463.9 | 335 | 141.7 | 467.4 | 270.3 | 599.9 | 399 | |||||

JSW-210SR | 5 | 238.1 | 366.6 | 543.7 | 446.3 | 816.8 | 712.8 | ||||||

8 | 194.8 | 446.3 | 482.6 | 354.4 | 756.5 | 622.2 | |||||||

7 | 351.5 | 526 | 421.5 | 262.6 | 696.2 | 531.7 | 970.9 | 800.7 | |||||

8 | 408.1 | 605.7 | 635.9 | 441.1 | 911.5 | 711.4 | |||||||

9 | 464.8 | 685.5 | 575.6 | 350.6 | 852 | 622.1 | 1128.4 | 893.6 | |||||

10 | 521.5 | 765.2 | 515.4 | 260 | 792.6 | 532.8 | 1069.8 | 805.6 | 1347 | 1078.3 | |||

11 | 578.1 | 844.9 | 733.1 | 443.5 | 1011.2 | 717.5 | 1289.3 | 991.5 | |||||

12 | 634.8 | 824.6 | 673.7 | 354.2 | 952.6 | 629.4 | 1231.5 | 904.7 | |||||

JSW-240SR | 5 | 377.2 | 509.68 | 684.48 | 552 | 1038.68 | 906.2 | ||||||

8 | 452.64 | 611.8 | 609.04 | 449.88 | 963.24 | 804.08 | 1317.44 | 1158.28 | |||||

7 | 529 | 713 | 533.6 | 348.68 | 886.88 | 702.88 | 1241.08 | 1057.08 | |||||

8 | 603.52 | 815.12 | 458.16 | 246.56 | 812.36 | 600.76 | 1165.64 | 954.04 | 1519.84 | 1308.24 | 1874.04 | 1662.44 | |

9 | 679.88 | 918.16 | 736 | 498.64 | 1090.2 | 854.92 | 1443.48 | 1206.15 | 1797.68 | 1560.32 | |||

10 | 755.32 | 1019.36 | 660.56 | 396.52 | 1014.76 | 750.72 | 1368.96 | 1104.92 | 1722.24 | 1459.12 | |||

11 | 860.76 | 1121.48 | 939.32 | 648.6 | 1293.52 | 1002.8 | 1633.35 | 1356.08 | |||||

12 | 906.2 | 1223.6 | 863.88 | 546.48 | 1217.16 | 900.68 | 1571.36 | 1253.96 | |||||

JSW-300SR | 5 | 671.6 | 976.15 | ||||||||||

8 | 805.92 | 1191.16 | 1210.72 | 788.44 | |||||||||

7 | 940.24 | 1366.2 | 1060.76 | 587.88 | 1762.72 | 1289.84 | |||||||

8 | 1074.56 | 1561.24 | 911.72 | 370.76 | 1613.68 | 1072.72 | 2315.64 | 1774.68 | |||||

9 | 1208.88 | 1756.28 | 1464.64 | 855.6 | 2166.6 | 4557.56 | 2868.56 | 2259.52 | |||||

10 | 1343.2 | 1952.24 | 1315.6 | 639.4 | 2019.56 | 1341.36 | 2719.52 | 2043.32 | 3421.48 | 2745.28 | |||

11 | 1477.52 | 2147.28 | 1867.6 | 1124.24 | 2569.56 | 1826.2 | 3291.52 | 2528.16 | |||||

12 | 1611.84 | 2342.32 | 1718.56 | 907.12 | 2420.52 | 1609.08 | 3122.48 | 2311.04 | |||||

JSW-400SR | 7 | 1690.04 | 2649.6 | ||||||||||

8 | 1932 | 3028.64 | 2346 | 1127 | |||||||||

9 | 2173.04 | 3406.76 | 2078.28 | 706.56 | 3576.04 | 2204.32 | |||||||

10 | 2414.08 | 3785.8 | 1809.64 | 286.12 | 3307.4 | 1783.88 | 4805.16 | 3281.64 | |||||

11 | 2656.04 | 4163.92 | 3038.76 | 1363.44 | 1536.52 | 2861.2 | 6034.28 | 4358.96 | |||||

12 | 2897.08 | 4542.96 | 2771.04 | 943 | 4268.8 | 2440.76 | 5766.56 | 3938.52 | 7263.4 | 543.36 | |||

13 | 3139.04 | 4921.08 | 4000.16 | 2019.4 | 5497.92 | 3517.16 | 6994.76 | 5014 | |||||

14 | 3380.08 | 5300.12 | 3732.44 | 1598.96 | 5230.2 | 3096.72 | 6727.04 | 4593.56 | |||||

15 | 3622.04 | 5678.24 | 3463.8 | 1178.52 | 4961.56 | 2676.28 | 6458.4 | 4173.12 | |||||

16 | 3863.08 | 6057.28 | 4692.92 | 2255.84 | 6189.76 | 3752.68 | |||||||

FAQ

| Questions | Answers |

|---|---|

| What are the advantages of stainless steel pneumatic actuators over aluminum ones? | Stainless steel models excel in corrosion resistance, suitable for offshore, chemical, and food/pharmaceutical industries; aluminum models are more cost-effective for general environments. |

| Can JSW stainless steel actuators be used in food-grade applications? | Yes. Core parts are made of food-grade stainless steel, and seals (Viton/NBR) are non-toxic, meeting hygiene standards for food processing. |

| What international standards do these actuators comply with? | They meet ISO5211, DIN3337, VDINDE-3854, and NAMUR standards, ensuring compatibility with global valves and accessories. |

| What is the function of dual independent external adjustment bolts? | They allow ±5° calibration at both open and close directions, ensuring precise valve control and easy maintenance. |